Aluminium decking is an investment and as such it needs to be robust enough to last, both in terms of safety and looks. As with all materials, the colour of aluminium decking may fade over a very long period of time, especially if it’s in direct sunlight - but it...

Continue ReadingAs hard as people try to protect their aluminum decking, accidents can happen. Dropping or dragging items across the surface can result in scratches or gouges, which can be very noticeable, especially if the boards are dark in colour. However, there are a few ways to reduce the risk of...

Continue ReadingAdek aluminium decking has been specifically designed with everyday living in mind, being extremely durable and long lasting. However, although very resilient, regular cleaning will help to keep it looking and performing at its best. How to clean aluminium decking Aluminium decking such as Adek is very easy to maintain....

Continue ReadingBased in West Malling, Kent, D1 Decking Solutions is a specialist supplier and installer of non-combustible decking. With 30 years' experience and a reputation for workmanship excellence, D1 Decking Solutions were appointed as the main contractor for Oakhill Park project, a scheme which involved the removal and replacement of unsuitable...

Continue ReadingThe honest answer is that you don’t! In these circumstances prevention is better than cure and ensuring that your aluminium decking does not become rusty or resisting the urge to paint it, will be better for its longevity and integrity. The most effective way of preventing rust is to keep...

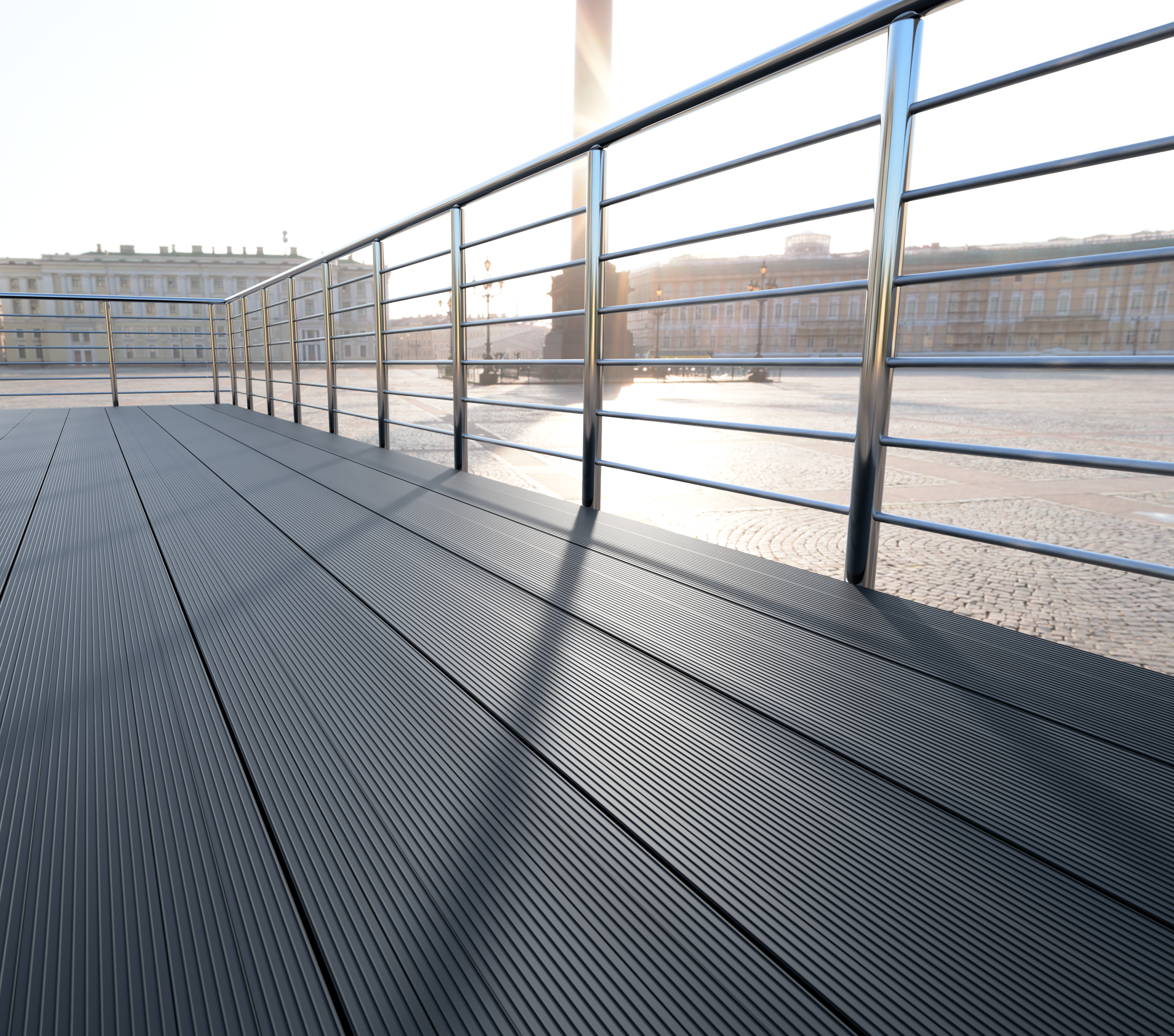

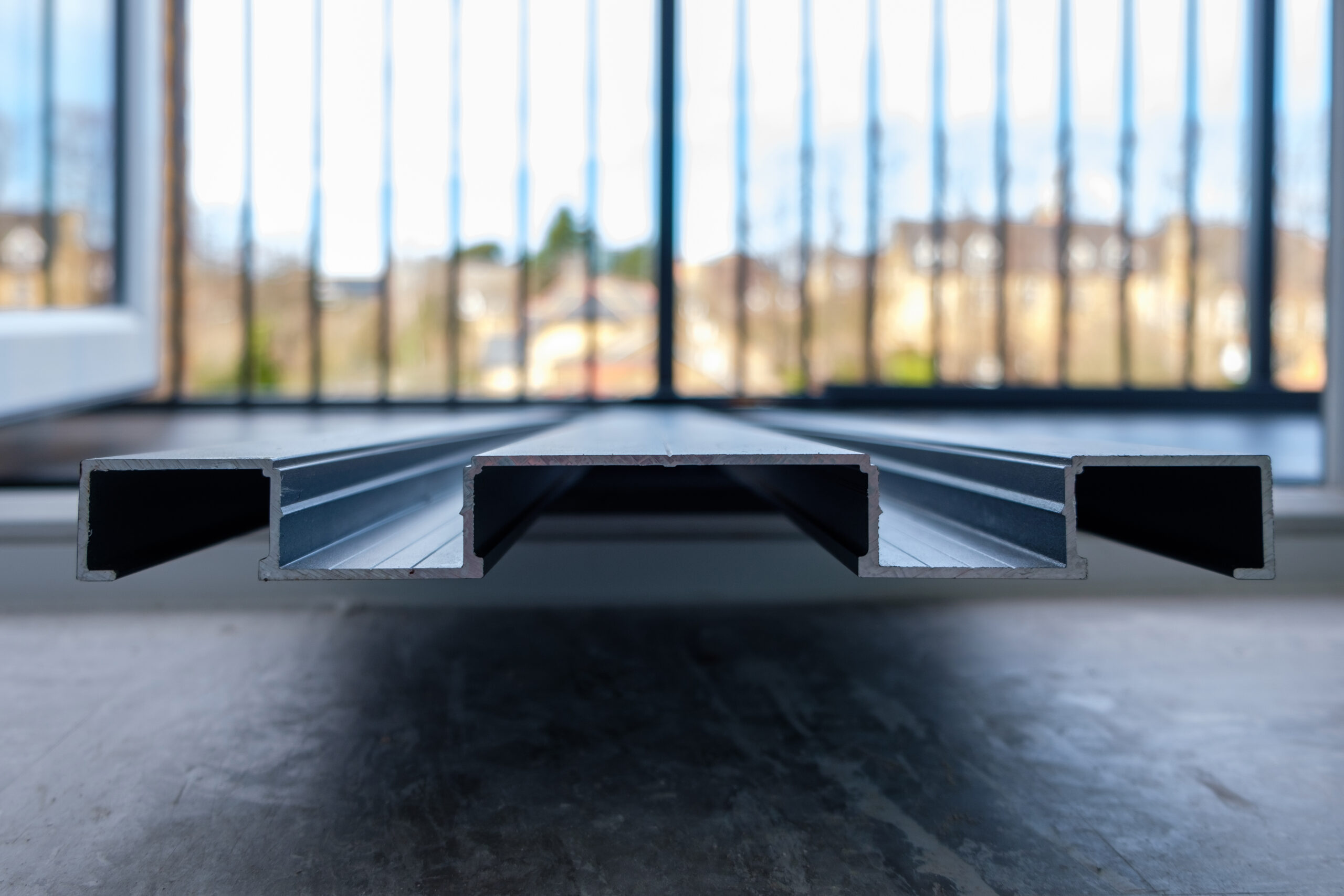

Continue ReadingAdek aluminium decking has been specifically designed for everyday living in mind, regardless of application. This means it is not only robust, long lasting, and stylish, but it is also extremely low maintenance. Adek aluminium decking and aluminium balcony decking requires no treatments or paints to protect its surface, and...

Continue ReadingAs hard as we may try to protect our aluminium decking, accidents can happen. Dropping or dragging items across the coated surface can result in scratches or gouges, which can often be very noticeable, especially if your aluminium decking is a darker colour. However, there are a few solutions which...

Continue ReadingThe short answer is no, your aluminium decking should not warp. However, there is a caveat! Whether you are fitting your aluminium decking yourself, or employing the skills of an expert, you must ensure that your aluminium decking is fitted and installed correctly. This will help to prevent any long-term...

Continue Reading